Mumunda wanhasi wekugadzira maindasitiri, kuenderera mberi kwehunyanzvi uye kufambira mberi mune tekinoroji zvakaunza kugona uye kunaka kugadzirwa. Semidziyo yechipfuyo yakatarisana, iyoNanimecond Laser Welding Machinezvishoma nezvishoma kuva sarudzo yekutanga kune vazhinji vagadziri veindasitiri. Hunhu hwayo hwekutsiwa hwakagadzikana, midziyo yakaderera simba rekushandisa, uye huwandu hwakanyanya hwemhando hwakaratidza kukosha kwakakosha muminda yakadai semotokari, kuEerishmance, uye michina.

I. Kuita kwakasimba

Kuita kwakasimba kweNanimecond Laser Welding Machinendechimwe chezvikonzero zvakakosha zvekuzivikanwa kwaro. Kugadzikana kwekushanda kwenguva refu ndeimwe yemanzwiro ayo akakurumbira. Kunyangwe pakushanda nguva dzose kwemaawa akati wandei kana kunyange mazuva, iyo Nanosecond Laser Welding Machine inogona kuramba ichichengetedza maitiro akagadzikana, uye hakuzove nekusvibiswa kwekuita kana kutadza kunokonzerwa nekushanda kwenguva refu.

Uye zvakare, iyo Nanosecond Laser Welding Machine ine yakanakisa shanduko kune shanduko yezvakatipoteredza. Kunyangwe mune yakakwira-tembiricha, yakakwirira-humidity kana yakaderera-tembiricha, nzvimbo yakaoma, inogona kushanda kazhinji isina kuvhiringidzwa nezvinhu zvekunze zvakatipoteredza. Izvi zvinonyanya kukosha munhamba yeAerospace, nekuti kugadzira spacecraft kazhinji kunofanirwa kuitwa pasi pemamiriro ezvinhu akawandisa

Ii. Midziyo yakaderera simba rekushandisa

Kuenzaniswa neyechinyakare michina michina, iyo Nanosecond Laser Welding Machine ine zviyero zviri pachena maererano nekushandiswa kwesimba. Sekureva kwehuwandu, iyo simba rekushandisa kweNanosecond Laser Welving Machine inenge 30% yakaderera pane iyo yeiyo yechinyakare arc tulat tulating michina. Izvi zvinoreva kuti mukunyora kwenguva refu maitiro, mabhizinesi anogona kuderedza zvikuru mari yemhando.

Ichi chimiro chekushaikwa kwesimba kusagadzikana hazvingabudisi zvakananga nezvebhizinesi, asi zvakare zvinosangana nezvinodiwa zvekuchengetedza simba uye kuchengetedza nharaunda munharaunda, uye zvinobatsira mabhisita ane mufananidzo wakanaka wemunharaunda.

III. Yakakwira Welding mhando

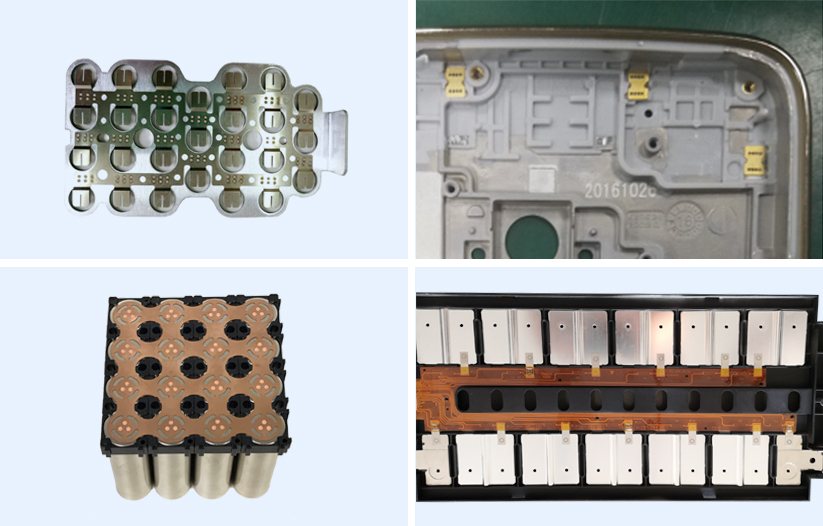

Iyo Nanosecond Laser Welding Muchina unoita zvine mutsindo maererano neyemhando dzemhando, uye dzinogona kuratidza zvakasiyana zvakasiyana kana muhutachiona hwezvinhu zvakasiyana kana kushandiswa kwemabasa akaoma.

Panyaya yeWalking yezvinhu zvakasiyana, iyo Nanosecond welaser welder muchina wemasimbi mitezo yakasarudzika yemasimbi, etumini.

Mukushandiswa kweyakaomarara maitiro, iyo Nanosecond Laser Welding Machine inogona kuzadza mabasa akakwira-akanyanya seyakavimbika Zvezvinwiwa zvakanyanyisa mumunda weAerospace, kurongeka kwayo kwakarongeka kunogona kusvika kune micron chikamu, chengetedza kuchengetedzeka uye kuvimbika kwendege.

Kana iwe uchitsvaga inoshanda uye yakakwirira-mhando yekudzivirira mhinduro, iwe unogona kufunga nezve Nanosecond Laser Weld

Kutumira Nguva: Jul-16-2024